MWS for Bukit Tua Development Project (2016 completion)

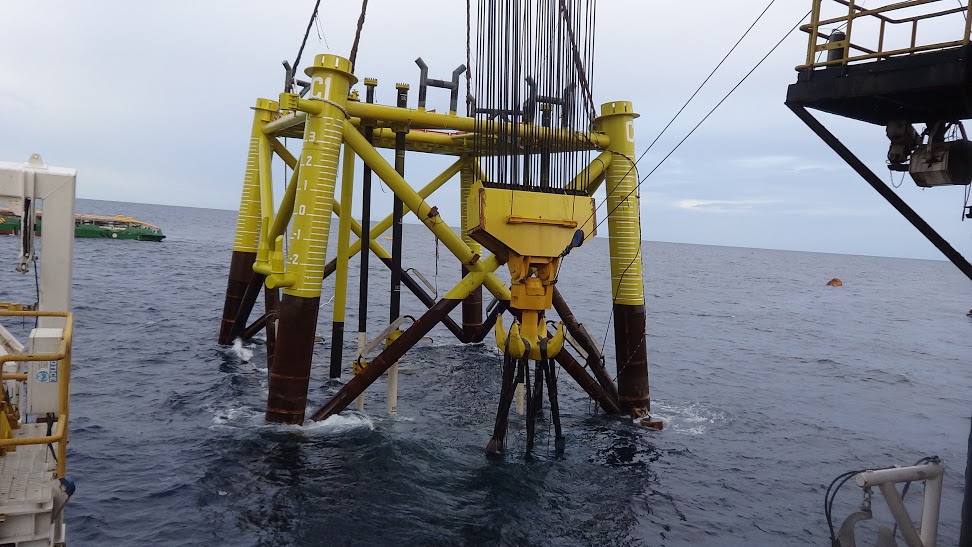

The 2nd Contract for the Bukit Tua Development Project consisted of a Wellhead Platform (WHP) topside with 4 legged jacket, 12” x 750m Export Gas Pipeline from an old WHP to a new WHP location, 8” x 700m (liquid) Infield Pipeline from WHP to FPSO PLEM, 16” x 700m (Wet gas) Infield Pipeline from WHP to FPSO PLEM and 12” x 700 m (Export gas) Infield Pipeline from WHP to FPSO PLEM.

Detailed Scope of Work for the Installation operations:

- Conduct suitability survey of barges or vessels for transportation and certification of seaworthiness at either their point of hire or on arrival at the transport departure location/field.

- Suitability of tugs boats and certification of seaworthiness at either their point of hire or on arrival at the transport departure location/fabrication yard.

- Witness the weighing of the Company facilities at fabrication contractor’s yard and review the weighing report.

- Review and approve major component of the load out procedures i.e. load out procedure for company facilities either by trailer/multi-axle/skidding/lifting, analysis and barge load out plans which shall include a review of tie-down and tow stability calculations prepared by the transportation and installation Contractor or Fabricator Contractor.

- Witness load out of jacket, topside, piles, conductors, pipelines and other appurtenances at fabrication sites.

- Inspect and approve tie-downs after loads are secured to the barge deck. Review, inspect and approve towing procedures and barge ballasting prepared by Transportation and Installation Contractor. Review and approve towing arrangement (including final survey of tugs to be used) and issue tow certificate.

- Loading arrangement and transportation study of platform and pipelines components which shall include a review of sea fastening and tow stability calculations.

- Review and approve jacket installation analysis; lifting, upending, piling, etc.; prepared by Transportation and Installation Contractor.

- Review and approve topsides installation analysis; lifting and etc.; prepared by Transportation and Installation Contractor.

- Review and approval of installation procedures prepared by Transportation and Installation Contractor for jacket, topside, piles, conductors or any other platform components.

- Review and approve installation procedures prepared by Transportation and Installation Contractor for pipeline, riser, flow line including analysis and procedure for pipe lay, riser installation or any other major installation activity.

- Review, witness and approve jacket position surveying procedure and result (as-built), prepared and executed by Transportation and Installation Contractor.

- Review, witness and approve pipeline (infield and export) and surveying procedure and result (as-built), prepared and executed by Transportation and Installation Contractor.

- Witness load out and attend sail away, approve towing arrangements and issue Certificate of Approval (C.O.A) for the transportation of jacket, topside, piles, conductors, pipelines and any major platform topsides components.

- Attend and witness offshore installation activities and issue Certificate of Approval (C.O.A) for the installation of the jacket, topside, piles, conductors, pipelines and any major platform topside components.

- Attend and participate in project management risk assessment, project kick off meeting, project load out meeting and any contingency planning meeting which are relevant to the above scope.

For more information, please visit our Projects.

For enquiry please Contact Us.